As the VP of Engineering at Redex for over 36 years, David Regiec, P.E. has been providing custom-designed gearboxes and components & systems to machine builders of all types.

New clients come to Redex USA when their existing solution does not meet specifications, or they have a new project that requires updated technology. Below are three examples of how Dave was able to provide custom engineering solutions based on a client’s specific needs.

Connect with Dave on LinkedIn or email him directly at dregiec@redex-group.com.

Case Study #1

Redex USA Provides Complete Automatic Lubrication System for Robotic 7th Axis

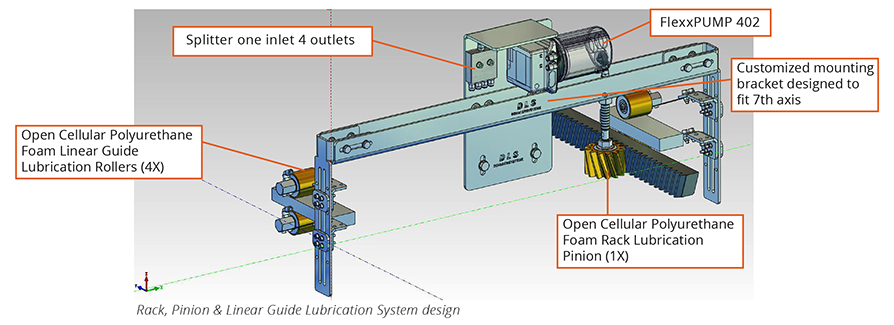

Rack, Pinion & Linear Guide Lubrication System

Installation 1

After approaching Redex, we designed and manufactured a completely automated lubrication system.

Installation 2

- Ensured that accurate quantities of lubricant were supplied.

- Allowed for easy monitoring.

- Reduced plant downtime.

- Increased safety (no need for maintenance technicians to enter the hazardous moving zone of robots).

- Was cost-effective.

Let Redex provide a customized solution for your assembly systems that will meet your budget.

Case Study #2

Redex Provides Critical Components For One of the World’s Top Aerospace Companies

X, Y, & Z Axis Drives on Automated Fiber Placement Machine

Electroimpact came to us because they had some unique challenges with the design of an Automated Fibre Placement (AFP) machine, which was to be used for the manufacture of large commercial aircraft structures (fuselages, wing skins, and spars). As part of their manufacturing process, they needed a precision gearbox in a unique torque and thrust range.

Redex TwinDRIVE Electrically Preloaded Zero-Backlash

To accomplish this, we offered the largest servo quality planetary gearboxes available in a ZERO-BACKLASH TwinDRIVE arrangement. This consisted of two planetary reducers electrically coupled together, racks, pinions, and an automatic lubrication system. This eliminated the backlash, insured precise position control and provided smooth acceleration up to 0.2g.

Let Redex can provide a customized solution for your assembly systems that will enhance your productivity.

Case Study #3:

Redex Develops a Less Expensive, More Effective Solution For VTL Turntable drives.

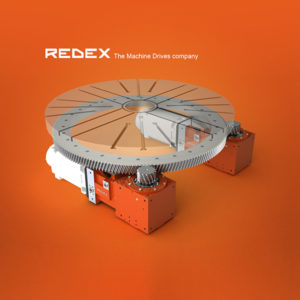

Redex Twin MSR Table Drive for Turning & C-Axis2

VTL Table Drive

Redex’s solution can be applied to new turntable designs or retrofits easily. Not only is it less expensive, but it is also compact too, taking up less space because the main drive motors are half the size of the conventional turning motor.